Basics of a Separately Excited DC Motor

A separately excited DC motor is a type of DC motor where the field winding is supplied from an independent source, separate from the armature winding supply. This configuration provides several advantages:

- Independent control of field and armature circuits

- Better speed regulation compared to other DC motor types

- Ability to operate above and below rated speed

- More stable operation under varying load conditions

The construction of a separately excited DC motor includes:

- Stator: Contains the field winding that produces the magnetic field

- Rotor (Armature): Contains the armature winding where the induced EMF is generated

- Commutator and Brushes: Facilitate the connection between the rotating armature and stationary external circuit

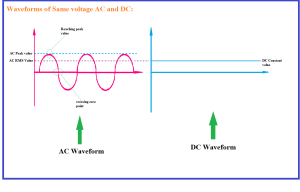

The fundamental speed equation for a DC motor is:

Where:

- N = Speed of the motor

- V = Applied voltage to the armature

- Ia = Armature current

- Ra = Armature resistance

- φ = Flux per pole (produced by the field winding)

This equation shows that motor speed is directly proportional to the back EMF (Eb = V – IaRa) and inversely proportional to the flux per pole.

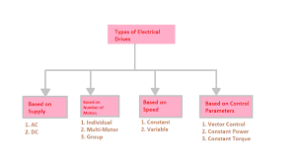

Armature Voltage Control

Armature voltage control involves varying the voltage applied to the armature while keeping the field flux constant. This method is used to control speed below the base (rated) speed of the motor.

By reducing the armature voltage from its rated value, the speed decreases proportionally since:

(with φ constant)

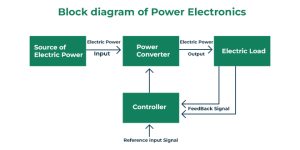

- Variable Voltage Supply: Using a variable DC source to directly control armature voltage

- Chopper Control: Using DC choppers to vary the average voltage applied to the armature

- Thyristor Control: Using controlled rectifiers to adjust the DC voltage level

- Provides constant torque operation

- Speed control is smooth and precise

- Efficient at all speeds

- Limited to speeds below rated speed

Field Control (Field Weakening)

Field control involves varying the field flux while keeping the armature voltage constant. This method is used to control speed above the base (rated) speed of the motor.

By reducing the field current, the flux per pole decreases, which increases the motor speed since:

(with V constant)

- Field Rheostat: Adding variable resistance in series with the field winding

- DC-DC Converter: Using electronic converters to control field voltage

- Provides constant power operation

- Speed can be increased above rated speed

- Reduced torque capability at higher speeds

- More economical for high-speed applications

Comparison and Applications

Both control methods have distinct characteristics that make them suitable for different applications:

- Ideal for applications requiring constant torque at variable speeds

- Used in electric traction for starting and low-speed operation

- Suitable for applications where precise speed control is needed

- Examples: Cranes, hoists, and conveyors

- Ideal for applications requiring constant power at variable speeds

- Used in electric traction for high-speed operation

- Suitable for applications where speed needs to exceed base speed

- Examples: Drilling machines, milling machines, and centrifugal pumps

In practice, both methods are often combined to achieve a wide range of speed control, from zero to several times the rated speed, making separately excited DC motors highly versatile for industrial applications.