Introduction to Electric Traction

Electric traction refers to the use of electric power for propulsion in railways. This technology has become the preferred method for train propulsion due to its numerous advantages over diesel and steam locomotives:

- Higher efficiency (over 90% compared to 35% for diesel engines)

- Lower maintenance requirements

- Reduced emissions at the point of use

- Quieter operation

- Better adhesion and faster acceleration

- Regenerative braking capabilities

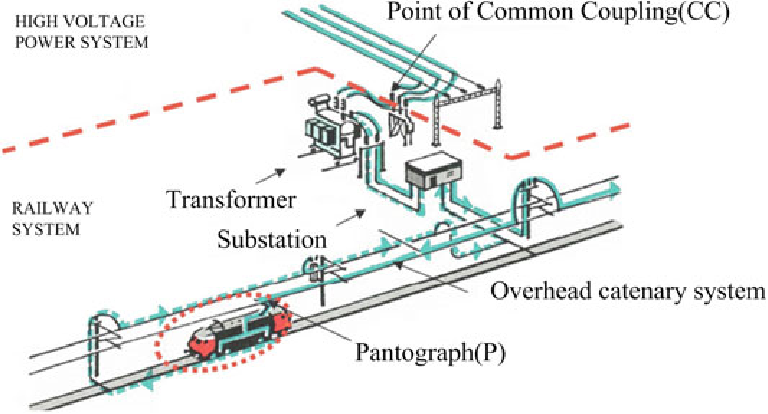

Electric trains receive their power supply from external sources through two primary methods: overhead line equipment (OLE) or third rail systems. The choice between these systems depends on factors such as cost, infrastructure requirements, and operational environment.

Overhead Line Equipment (OHE)

The overhead line system is the most common method of power delivery for electric trains. It consists of:

- Contact Wire: The wire that makes direct contact with the train’s pantograph

- Support Structures: Poles or gantries that hold the overhead wires

- Messenger Wire: A stronger wire that supports the contact wire

- Insulators: Prevent current leakage to the support structures

The pantograph is a folding device mounted on the train roof that collects power from the overhead wires:

- It maintains constant pressure against the contact wire using springs or compressed air

- Carbon strips on the pantograph head ensure good electrical contact

- The pantograph can be lowered for maintenance or when passing under bridges

- Modern trains may have multiple pantographs for redundancy

Overhead systems typically operate at high voltages (15kV AC or 1.5kV DC) to minimize power losses over long distances.

Third Rail System

The third rail system is primarily used in urban transit systems like subways and light rail. In this configuration:

- A third rail, in addition to the two running rails, carries the electrical power

- Voltages are typically lower (600-750V DC) for safety reasons

- A “shoe” collector on the train makes contact with the third rail

- The system is less expensive to install than overhead lines

While more cost-effective, third rail systems have safety concerns since the power rail is at ground level, posing risks to people and animals. For this reason, they are mostly used in controlled environments like tunnels and fenced tracks.

Completing the Circuit

For electricity to flow and power the train, a complete circuit must be established:

- Current flows from the substation through the overhead wire or third rail

- The train’s motors use the current to produce mechanical power

- The current returns to the substation through the running rails

- This return path is crucial for proper operation and safety

Special attention is paid to the return current path to prevent electrolysis and interference with signaling systems. Insulated joints in the rails help manage the return current flow to designated substations.

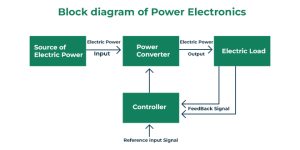

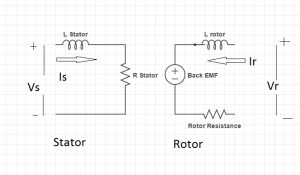

Power Conversion and Control

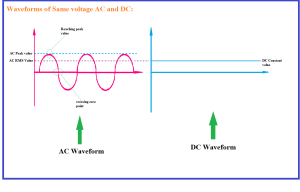

Modern electric trains use sophisticated power electronics to convert the incoming power to the appropriate form for the traction motors:

- AC overhead systems require transformers to step down the voltage

- Rectifiers convert AC to DC in some systems

- Inverter systems convert DC back to variable frequency AC for AC motor drives

- Regenerative braking feeds power back into the supply system